I’m eternally embarrassing my husband when we go out to eat.

If the restaurant meal isn’t as I ordered it, I have no hesitation about sending it back, politely, and this is a constant source of humiliation for my hubby. But here’s the thing, I don’t want anyone to feel bad. I don’t want any special treatment in the form of free dessert or a reduced check at the end of the meal.

I actually want to help.

The cliché is that mistakes are opportunities for growth, right? For me, this tired saying has merit. In a restaurant, in business, in education, in almost anything. If the chef and the server do not know there’s been a mistake, and neither is allowed the opportunity to fix it, they cannot learn from their mistake.

As a customer, I want to give them a chance to fix it, because as an employee of a small business, I would like an opportunity to fix a mistake rather than lose that business.

As a former educator, I know that students sometimes fail before they really learn.

As a mother, I think that letting my child stumble will give him a chance to learn to pick himself up.

At Science Take-Out, we are practically allergic to mistakes. However, a recent error with a kit gave us a chance to learn from our mistake.

One of our long-time teacher customers wrote to us saying that the “Keeping a Balance: Homeostasis and Negative Feedback” kit she ordered didn’t work well. The color changes were off. Occasionally, the liquids in a kit here or there may go astray. Maybe temperature changes or a lengthy stay on the shelf may affect its efficacy. We guarantee our products, so we always replace the offending kit.

However, in this case, we received worse news: she reported that her kits hadn’t worked well in two years.

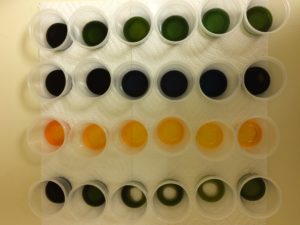

This revelation set off a chain reaction: Was is a kit manufacturing issue? Was it a problem with the kit reagents? Our staff spent numerous hours over several days carefully going through every part of the kit to figure out the problem. We pulled a kit from inventory and did it as if we were students in a classroom. We picked out our stock bottles and did the experiment from those li quids.

quids.

We identified the problem. About two years ago, we had changed manufacturers for bromothymol blue, the chemical that we use for “Cupple Blood”. This affected the intensity of the color change, and caused a slight difference in the way that the colors look for the activity.

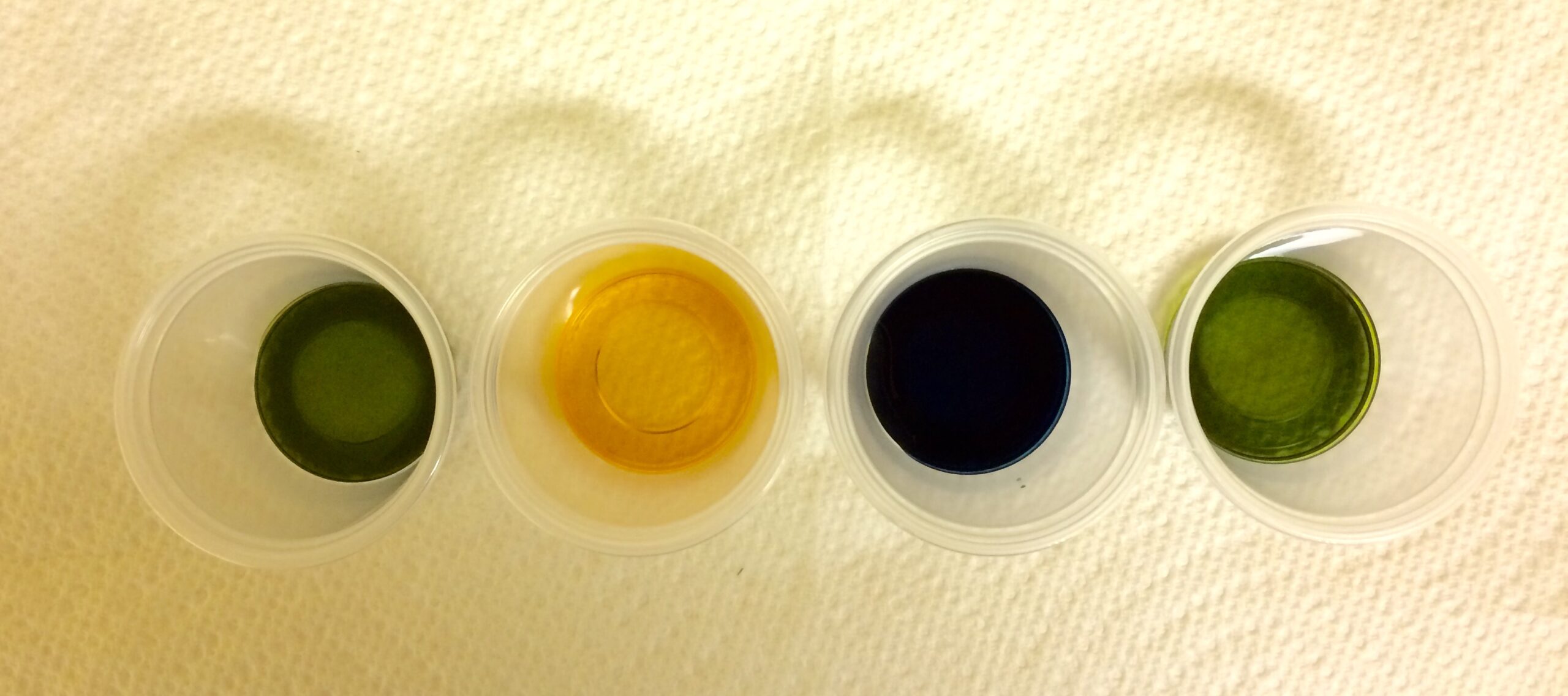

Now that we figured out the problem, we needed to figure out a way to fix it. This required that we change the concentration of bromothymol blue that we use for the “Cupple Blood”. We spent an afternoon in our lab, tweaking the concentrations of the kit reagents to make sure that the “Cupple Blood” color change activity is working well.

I want to end with saying how important it is for our customers to feel that they can contact us anytime about any problems that they are having with any of our kits. We will turn an error into a learning experience – and make lemonade out of lemons.